About Us

The RIKEN KEIKI Group contributes to societal progress based on the enduring theme: realizing environments in which people can work with peace of mind.

For more information

-

Message

-

Company

Overview -

Business

Overview -

Executive

Team -

Philosophy

& Policies -

History

-

Our Logo

-

Locations

-

Learn more

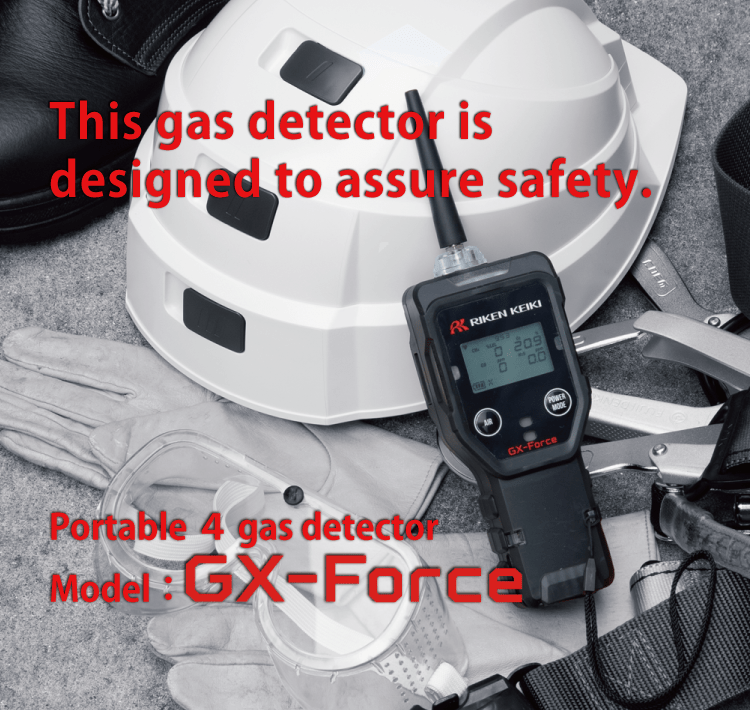

PRODUCTS

The RIKEN KEIKI product lineup includes more than 100 types of gas detectors and environmental monitoring products.

See here for information about RIKEN KEIKI Group products.

IR

To Shareholders and Investors

See here for the latest disclosure documents,

IR materials, and other data for RIKEN KEIKI Co., Ltd.

Sustainability

Striving to realize a society in which all can live with peace of mind, the RIKEN KEIKI Group advances corporate social

responsibly (CSR) initiatives to help achieve the Sustainable Development Goals (SDGs).

For more information

For more information