HOME > Sustainability > Social > Quality initiatives

Quality philosophy

Quality philosophy

The company has established a quality management system and secures the necessary management resources in line with the enduring theme of our management philosophy—realizing environments in which people can work with peace of mind—which guides us in contributing to societal progress. Under this system, we contribute to society through the timely provision of products of the highest quality that meet customer needs.

Action guidelines

- We will comply with all rules governing the quality management system.

- We will strive to incorporate customer needs in all internal processes, from product development through auxiliary services.

- In addition to complying with all applicable requirements, we will strive to improve our quality management system on an ongoing basis.

- We will set annual quality targets and review them periodically as part of ongoing efforts to implement improvement activities.

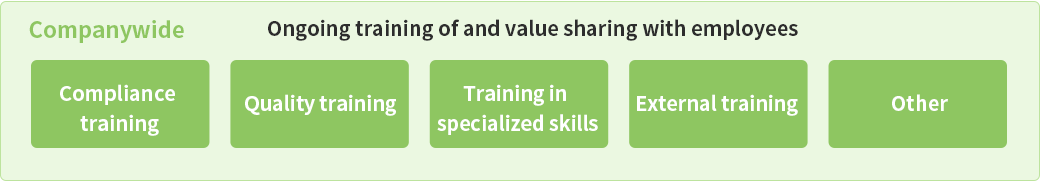

- We will ensure that employees are aware of, understand, and comply with all quality policies.

- In addition to periodic reviews by management, these policies will be revised in accordance with changes in customer needs and other factors.

- These policies will be published on the Company website.

Plan A of the quality assurance system

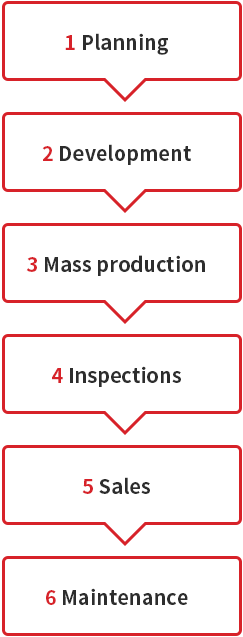

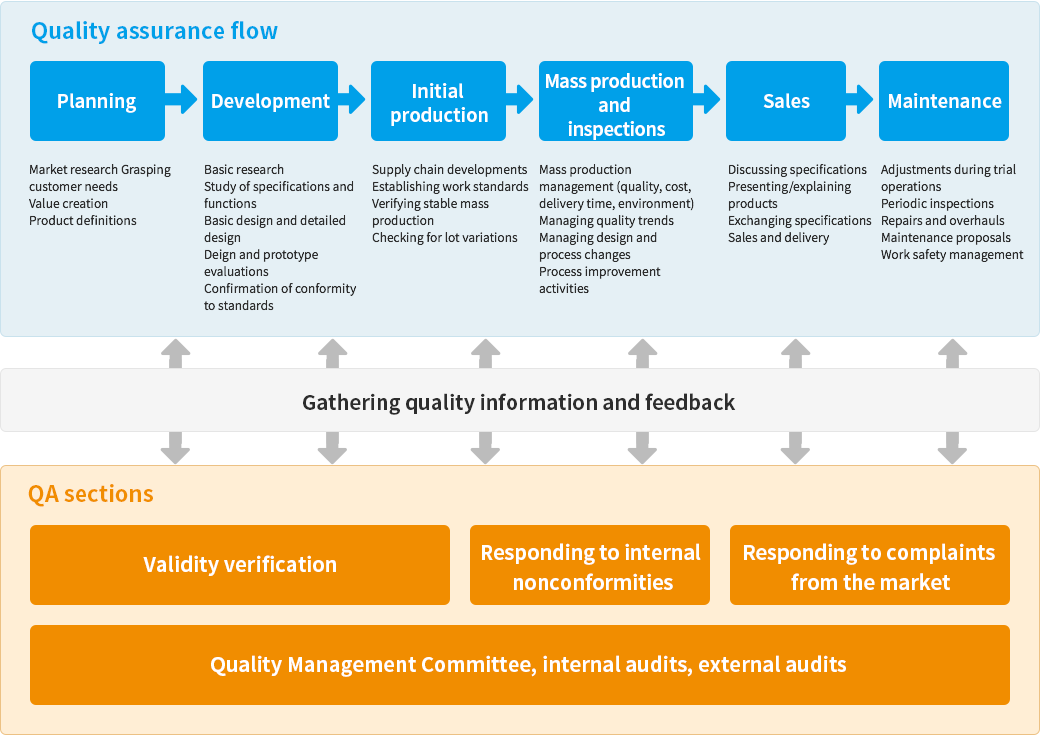

We implement a wide range of initiatives to ensure reliable quality in all processes, ranging from planning and development through manufacture, sale, and maintenance, to deliver to all customers products that transform invisible risks into visible security, at any time and in any situation.

-

The Planning and Development Committee deliberates on and makes decisions concerning development themes and pursues development efforts based on various inputs, including customer needs.

As an operational structure for product development processes, the Company deploys a project-based structure involving personnel in charge from the Sales Division and Development Division.

Final prototypes completed by a project group are subject to quality assessment testing (validity confirmation) by quality assurance sections to confirm they meet the specified design requirements.

We proceed to the mass production stage only after evaluating the initial production of new products for which validity has been confirmed.

The mass production process involves procuring necessary components from our supply chain and meeting work standards that specify in detail matters such as assembly and inspection methods.

Products passing shipping inspection are stored for specific periods of time in our product warehouses, in accordance with the specified storage conditions, then shipped in response to customer orders.

Sales staff with deep knowledge of our products propose solutions addressing various aspects related to products suited to individual users through the development of system software.

We assign field engineers to maintain our products at each service station. Given the need among maintenance staff for high technical skills and decision-making capabilities, we certify as field engineers only those individuals who have completed specialized training and have been assessed to possess the necessary skills.

Quality management system (QMS) certification

The Company seeks to assure global standard quality not merely through certification under the ISO 9001 international Quality Management System standard, but through plant conformity reviews under the ISO 80079-34 international standard on quality management systems for the manufacture of devices used in explosive atmospheres.

| ISO9001:2015 | |

|---|---|

| Review agency | High Pressure Gas Safety Institute of Japan ISO Review Center |

| Scope of certification | Design, development, manufacture, and maintenance of gas detector and alarm equipment and other measurement instruments |

| Subject sites | Headquarters, Development Center, Production Center, Hakodate Factory |

| Registration no. | 95QR・007 |

| Registration year | 1995 |