Reason for Riken’s growth

- 1What does

RIKEN KEIKI do? - 2What are the strengths of

RIKEN KEIKI? - 3What is RIKEN KEIKI aiming for?

- 4RIKEN KEIKI in numbers

1What does RIKEN KEIKI do?

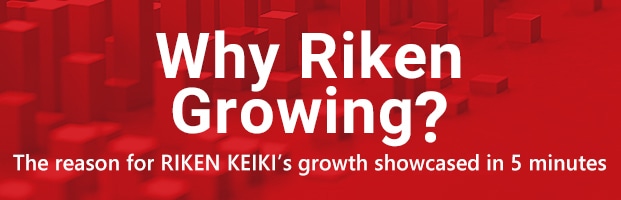

From commercialization of optical interferometric gas detectors to becoming an industrial gas detection and alarm equipment manufacturer

In 1939, RIKEN KEIKI Co., Ltd. was established to commercialize and mass produce the optical interference gas detector invented at the Institute of Physical and Chemical Research (RIKEN).

From the 1920s, when coal was the main energy source, explosions in coal mines and oil tankers occurred frequently. Our technology started with a gas detector to help preventing industrial disasters in coal mines and explosions in tankers.

Today, as an industrial gas detection and alarm equipment manufacturer, we have grown to have consolidated net sales of 49.0 billion yen and continue to protect the safe working environments in various fields.

- Established in 1939

- Industrial gas detection and alarm equipment manufacturer

- Growth to 49.0 billion yen

2What are the strengths of RIKEN KEIKI?

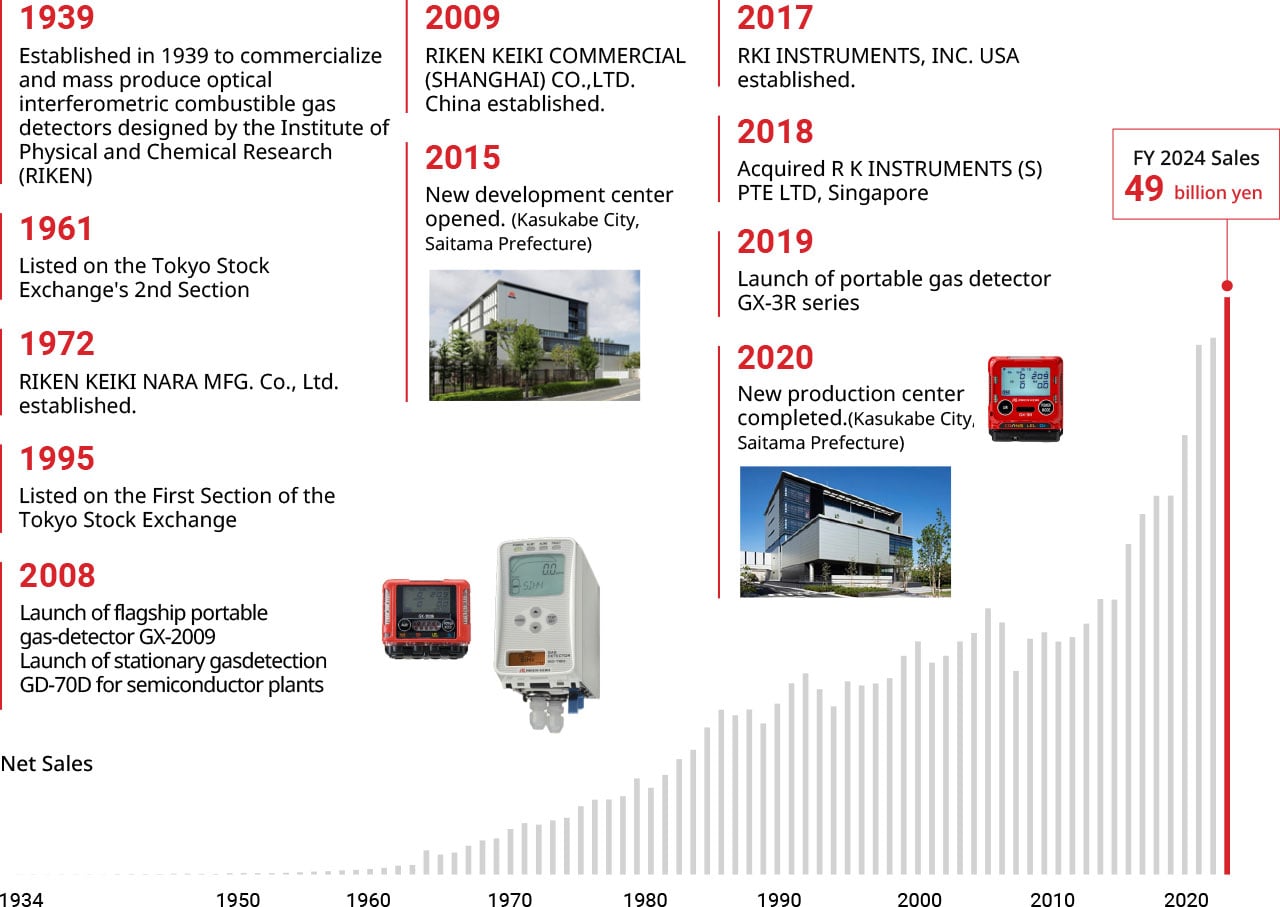

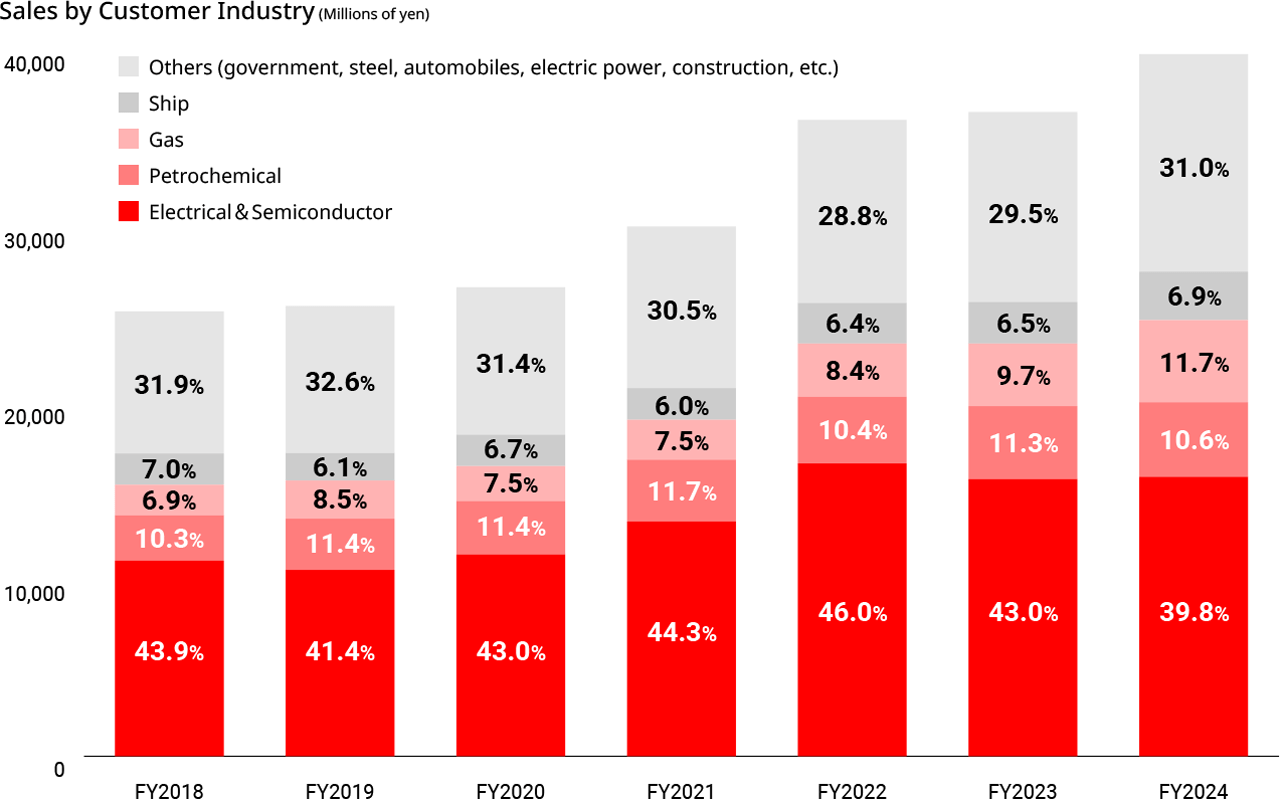

Approximately 70% market share in the semiconductor industry (Japan)

The 1980s was the dawn of Japan’s semiconductor industry.

The generation of toxic gases that are extremely harmful to the human body during the semiconductor manufacturing process has led to a need for gas detection systems that can detect semiconductor material gases.

We were the first company to develop and provide a gas sensor for such a low level of concentration gas detection in Japan. In addition, we were able to deliver not only gas detection alarms but also instrumentation panels incorporating sampling equipment and touch panels to major semiconductor manufacturing factories. The data of a large number of gas detectors is centrally managed through instrumentation panels, making them a high-value-added product where it is difficult for other companies to enter the market with their stand-alone products.

About 40% of our net sales are to the semiconductor industry, and the market share of gas detectors for domestic semiconductor factories remains at a top level of 70%.

Gas sensing technology developed in-house

We have the advantage of developing most of our gas sensing technology in-house. A development center and a production center were established in the city of Kasukabe in Saitama Prefecture in 2015 and 2020, respectively, as bases for gas sensor development and gas sensor production.

By considering customer requests at the maintenance stage when developing new products, we are constantly coming up with sensing technologies that meet customer needs. For example, we have developed a potentiostatic electrolysis method sensor, which is widely used in semiconductor factories, and a catalytic combustion method sensor, which is used in a wide range of work sites, and developed the “Opt-Sonic” sensing principle, which combines and advances the optical sensor, since our foundation, with the sonic sensor.

Interference gas removal filters are also one of our essential sensing technologies. Detecting the presence of untargeted gas in the atmosphere can lead to false detection. Interference gas removal filters are placed in front of the sensor to achieve highly accurate detection.

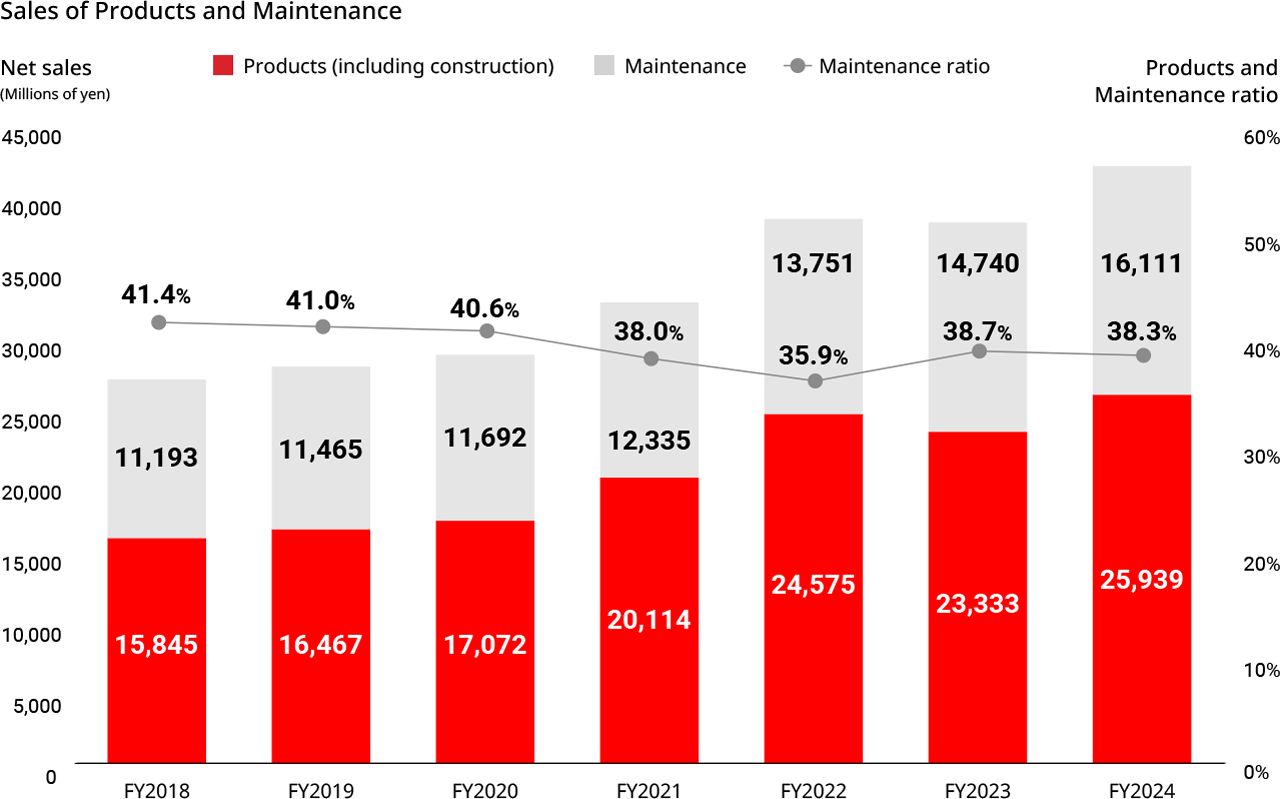

Stable maintenance business that is less affected by the economy

Our involvement in gas detection does not end after they have been delivered or installed. Periodic maintenance after the product is purchased is required because the sensitivity gradually decreases if gas detectors are being used continuously.

Periodic maintenance includes checking whether the gas concentration can be accurately measured, performing calibration work if there is a deviation from the initial setting, replacing gas sensors, and replacing consumables such as pumps, flow sensors, and interference gas removal filters at regular intervals. We have established a mature after-sales maintenance network in Japan and overseas in various parts of Japan, overseas subsidiaries, and overseas dealers.

As safety management is required as long as the factory is in operation, a gas detector needs to be inspected and maintained regardless of the ups and downs of the economy, and stable business is expected.

- Approximately 70% market share in the semiconductor industry (Japan)

- Gas sensing

technology developed in-house - Stable maintenance demand that is less affected by the economy

You can check the business status of RIKEN KEIKI.

3What is RIKEN KEIKI aiming for?

Expand overseas business

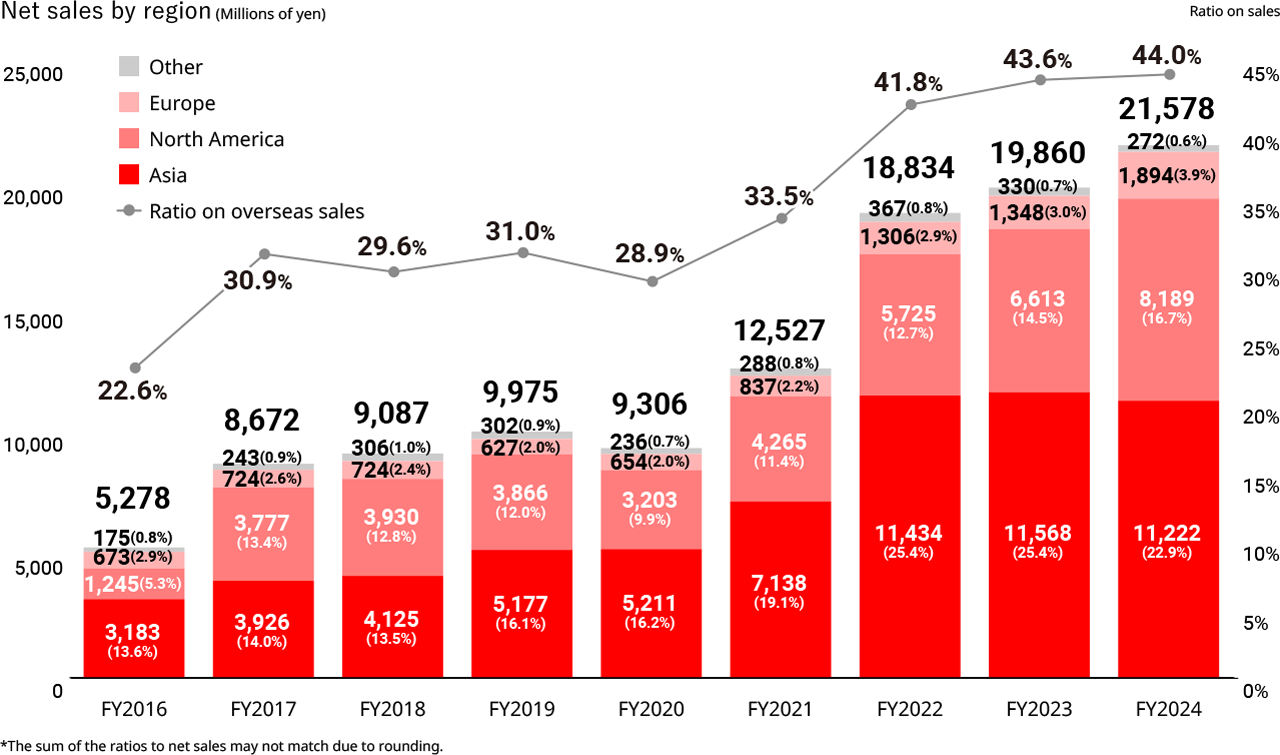

RIKEN KEIKI is expanding its sales to overseas markets by utilizing its know-how in sensing technology and maintenance services cultivated in Japan.

Over the last 10 years, our strategy to expand our overseas sales has been to develop products that meet global standards applicable to overseas markets, establish a system for overseas subsidiaries and expand their overseas sales network by increasing share ratio to a wholly-owned subsidiary.

As a result of focusing on overseas business, mainly in Asia and North America and other areas, the ratio of overseas net sales reached 44.0% in the fiscal year ended March 31, 2025, compared with 22.6% in the fiscal year ended March 31, 2017.

From a medium- to long-term view, we expect that demand for gas detection for semiconductor factories will continue to grow as information technology advances, as the IoT and AI technology spread, and as the market for EVs (electric vehicles) expands, and we will continue striving to boost our overseas ratio.

Expectations in the methanation field

One of the area of interest over the medium term is the field of methanation.

Carbon neutrality and decarbonization are expected to advance significantly in the manufacturing industry toward the realization of a sustainable society, and the development and social implementation of next-generation energy technologies, such as methanation technology, which synthesizes CH4 (methane) from CO2 (carbon dioxide) and H2 (hydrogen), are being pursued. By combining our sensing technology of gas detectors and gas calorimeters, we are offering a composite sensing technology that is further ahead of the “Opt-Sonic” technology that has developed our original optical sensor, for contributing to its implementation in society.

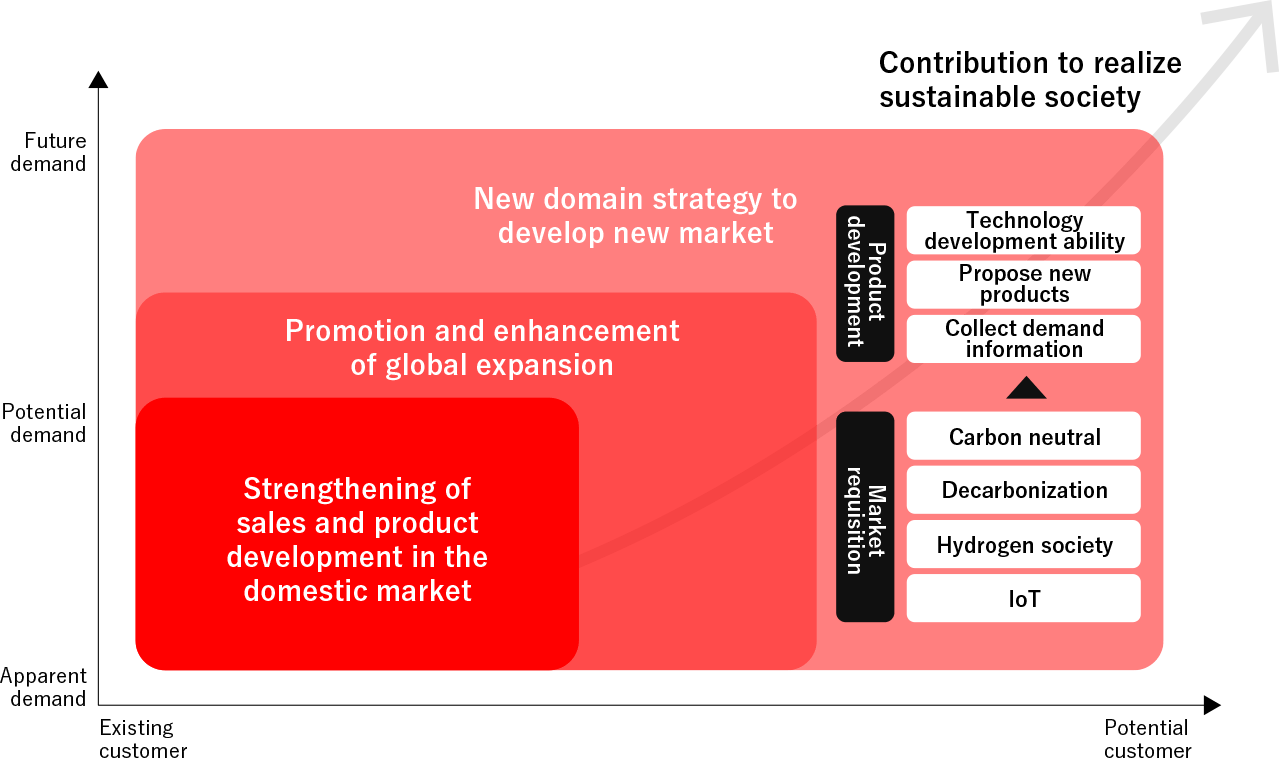

Medium-term Management Vision

We have newly set our medium-term management vison of “in response to sustainable social and customer needs such as IoT and decarbonization, the RIKEN KEIKI Group aims to develop new technologies and expand overseas markets to become a global company that achieves sustainable growth by utilizing the power of ‘people’ and ‘technology,’” and the RIKEN KEIKI Group will lead its development of technologies and commercialization, including basic development, to contribute to realizing a sustainable society.

- Increase market share in overseas markets

- Expectations in the methanation field

- Achieve sustainable growth by mid-term management vision

You can see the targets set forth by RIKEN KEIKI and the path to reach them.

4RIKEN KEIKI in numbers

- Established in1939

- Market share for

the domestic

semiconductor

industry

Approximately 70% - Consolidated

net sales

for the fiscal year

ended March 31, 2025:49.0billion yen - Overseas

net sales ratio

for the fiscal year

ended

March 31, 2025:44.0% - Medium-term

net sales target

for the fiscal year

ending March 31, 2026:50.0billion yen